Chemical industry

Release time:

2025-02-28

1. Project Overview

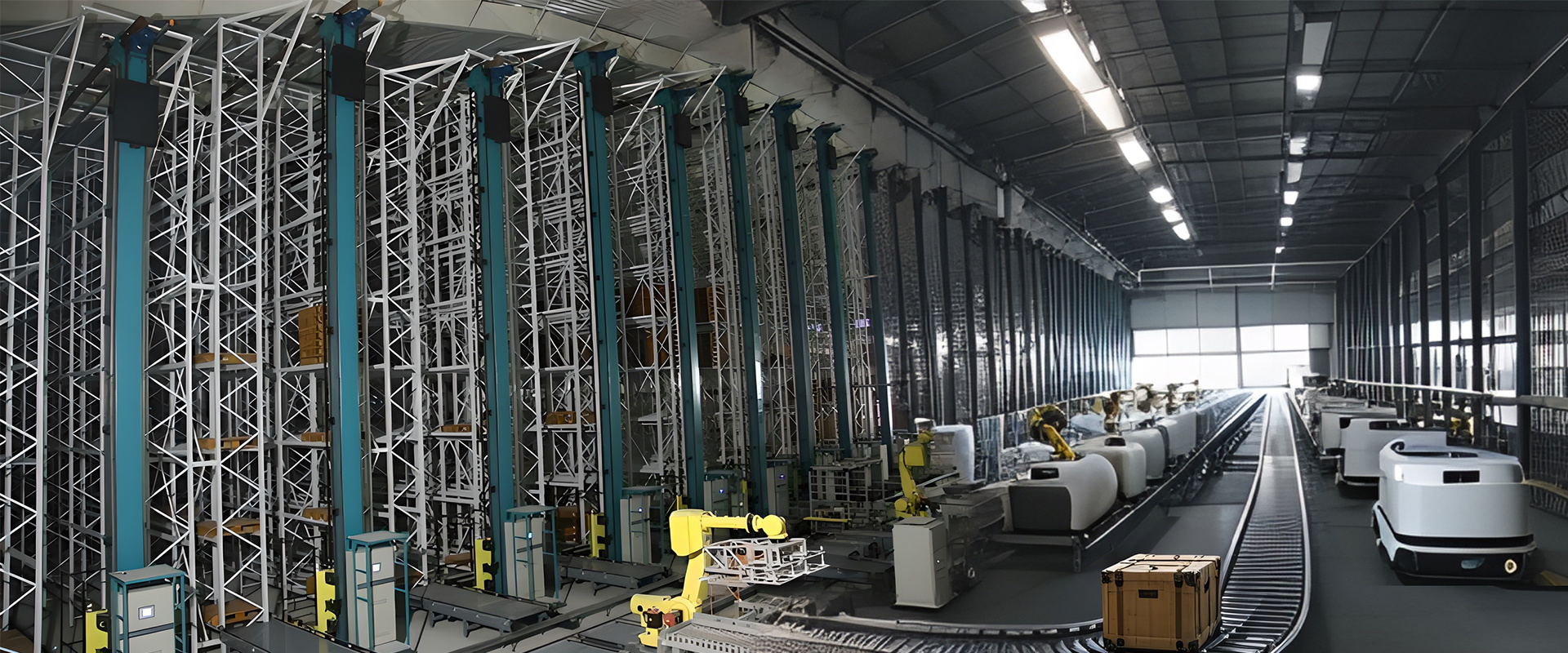

KEDLE SMART built an intelligent automated warehouse for a large chemical enterprise to address issues such as low warehousing efficiency, high labor costs, and significant safety hazards. The project utilizes an automated warehouse system to achieve intelligent management of the entire packaging, warehousing, and outbound process. It is suitable for storing Class C solid materials (such as lubricating oil and butane/pentane chemicals). The project includes two warehouse areas: A and B.

- Area A: 9872 storage locations, 4 stacker cranes, 1 conveyor system, 1 control system.

- Area B: 16320 storage locations, 5 stacker cranes, 1 conveyor system, 1 control system.

The warehouse uses a multi-layer rack structure, achieving a storage density 7-10 times that of a traditional flat warehouse. It strictly adheres to the "Fire Prevention Design Standard for Petrochemical Enterprises," featuring a 6-meter-wide circular fire lane and an independent wall, meeting fire safety distance requirements.

2. Key Technologies

- Intelligent System Integration: WMS+WCS system, achieving automated inventory management, batch tracking, and First-In, First-Out (FIFO), supporting seamless integration with the upper-level system.

- Automated Equipment: Stacker cranes with precise positioning (±3mm error), supporting high-speed access, equipped with redundancy design and variable frequency speed regulation technology.

- Efficient Logistics Management: An overhead walkway connects the production workshop and the warehouse, shortening material transportation distances and improving flow efficiency.

- Environmental Adaptability: Uses high-temperature resistant and corrosion-resistant materials and is equipped with a temperature and humidity monitoring system to ensure the safe storage of chemicals.

3. Economic Benefits

- Labor Costs: Reduced forklift operators by 15, saving approximately RMB 1.4 million in annual labor costs.

- Equipment Maintenance: Reduced traditional forklift procurement and maintenance costs by RMB 2.2 million.

- Material Loss: Automated handling reduces breakage rates, resulting in approximately RMB 150,000 less in annual losses.

- Storage Capacity: Storage capacity increased by 5 times.

- Operating Speed: Inbound efficiency doubled, loading capacity reached 250 tons/hour, and the logistics cycle was shortened by almost half.

- Safety and Sustainable Development: Unmanned operation eliminates human-machine interaction risks, achieving zero major safety accidents.

Previous Page

Next Page

WeChat

WeChat